The following points highlight the top eight applications of genetic engineering in industry. The applications are: 1. Protein Engineering 2. Metabolic Engineering 3. Pharmaceutical Industry 4. Biodegradable Plastic Industry 5. Oil Industry 6. Bio-Hydrometallurgy 7. Bio-Mineralisation 8. Fuel Industry.

Application # 1. Protein Engineering:

Protein engineering involves insertion of chemically synthesised DNA into desired organisms to produce modified proteins. These techniques made it easy to alter one or few amino acids in a protein and thus alter its structure and behaviour.

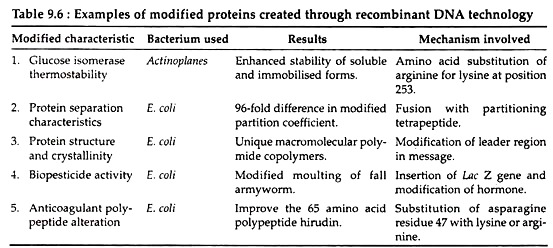

In this way, enzymes and bioactive peptides used in different industries can be created with different characteristics. Table 9.6 summarizes a variety of modified proteins and bioactive peptides that has been created using bacteria.

In addition to bacteria, yeasts are becoming more important in the production of recombinant proteins that have particular biomedical importance. The most commonly used yeast is Saccharomyces cerevisiae. It is used for the production of vaccines for hepatitis B virus and malarial protozoa, therapeutic agents like insulin, insulin like growth factor, blood coagulating factor, fibroblast growth factor, platelet-derived growth factor etc., diagnostic kits for hepatitis C virus protein, HIV-1 antigen etc.

Application # 2. Metabolic Engineering:

ADVERTISEMENTS:

Application of genetic engineering in protein industry has progressed so much that an entirely new field has merged, called metabolic engineering. In this application of recombinant DNA technology metabolic networks are restructured by the recruitment of proteins from different cells.

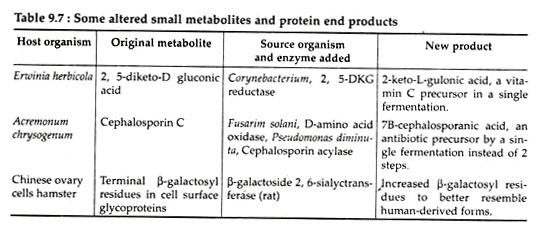

It results in a change in pathway distribution and rate. By combining the metabolic capabilities from two organisms entirely new products and intermediates are being synthesised. Examples of some altered small metabolites and protein-related end products are given in Table 9.7.

Application # 3. Pharmaceutical Industry:

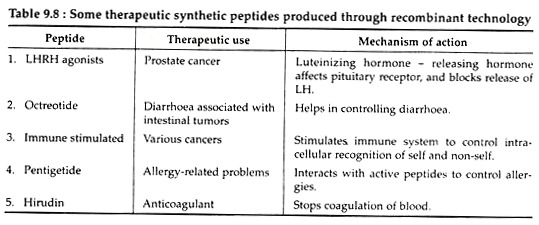

Through metabolic engineering a number of synthetic medical peptides have been produced with the help of recombinant DNA technology (Table 9.8). All such genetically engineered products show least harmful side-effects.

Application # 4. Biodegradable Plastic Industry:

Biodegradable plastics like polyhydroxylbutyrate (PHB) can be obtained commercially by fermentation with the bacterium Alcaligenes eutrophus. But its production cost is very high. Recently three genes, viz., phbA, phbB and phbC encoding the enzymes 3- ketothiolase, acetoacetyl-CoA reductase and PHB synthase have been isolated from A. eutrophus.

These genes were introduced into a model plant Arabidopsis which produced PHB globules exclusively in their chloroplasts without affecting plant’s growth and development. The amount of PHB in the leaves of this transgenic plant was up to 10 mg/g fresh weight. Industry has already started to explore the production of biodegradable plastics from other transgenic tree plants like poplar.

Application # 5. Oil Industry:

Plants store oil in their seeds (e.g., ground nut, mustard, rapeseed, sunflower, sesamum, soya bean etc.) or in fruits (e.g., olive, avocado, oil palm etc.). Such vegetable oils are used either as food or in industrial purposes. According to various requirements the fatty acid quality and yield can be improved by using genetic engineering technology.

ADVERTISEMENTS:

For example, the wild type canola (rapeseed) contains 60% oleic acid along with some other fatty acids. A genetically engineered canola was constructed with a single gene from the California bay tree that encodes an enzyme involved in the synthesis of lauric acid. These transgenic canola seeds contain 60% lauric acid instead of 60% oleic acid; the new oil resembles the oil found in coconut and palm oil.

Similarly, a genetically engineered soya bean with desirable monounsaturated fatty acid content of about 25% oleic acid to over 85% in its oil has been developed. Such improved variety of soya bean oil is very good for health. The production of such genetically engineered oil has already been commercialized.

Application # 6. Bio-Hydrometallurgy:

Bio-hydrometallurgy is a new branch of metallurgy that amalgamate metallurgy and biotechnology together. Extraction of metals from ores through conventional metallurgy involves smelting ores at high temperature, a process which is very much polluting and energy intensive approach.

However, bio-metallurgy is an approach which is environment friendly and can be used to extract metals from low grade ores in contrast to high grade ores used in conventional metallurgy which are gradually becoming exhausted.

In bio-metallurgy, different bacterial species are being used for the extraction of metals from ores. For example, Thiobacillus ferrooxidans and related thiobacilli are used for copper extraction. Recently, genetically engineered strains of thiobacilli have been developed to increase the speed of extraction.

Such bacterial strains have increased resistance to arsenite and arsenate (which do not allow bacterial growth) and increased recovery of gold from arsenopyrite-pyrite ores.

Application # 7. Bio-Mineralisation:

It has been shown recently that some bacteria which are normal constituents of soil can deposit valuable metals like gold, silver etc. in soil. It is suggested that negatively charged polymer on the outside of the bacteria, attracts the positively charged gold particles in the soil. Thus, the metal particles clump together as grains that eventually form gold nuggets.

The process of gold deposition on the negatively charged polymers can continue even after the death of the bacteria. Naturally occurring bacteria involved in such biomineralisation include Bacillus cereus, podomicrobium-like budding bacteria and Chlorella vulgaris.

It is suggested that genes responsible for mineralization in a variety of microbes can be isolated, cloned and transferred into E. coli, which may then help in metal deposition more efficiently.

ADVERTISEMENTS:

Application # 8. Fuel Industry:

In recent years, ethanol has found its use as an important chemical feedstock and as a fuel supplement. Ethanol is generally produced by fermentation of some sugar (starch, cellulose) rich products with the help of yeast, Saccharomyces cerevisiae or sometimes with Kluyveromyces fragilis.

At present E. coli and Klebsiella planticola carrying genes from Z. mobilis have been developed which could utilize glucose and xylose as the substrate to give maximum yield of ethanol.