The following points highlight the two main ways of poultry rearing. The ways are: 1. Free-Range or Extensive System 2. Indoor or Intensive Method.

Way # 1. Free-Range or Extensive System:

This is the oldest system of farming used by general farmers, where there is no shortage of land and monetary involvement. Free range poultry farming consists of poultry birds permitted to roam freely instead of being contained in any manner. It is practised in rural area in small scale. A free range chicken must have daytime access to open-air runs during at least half of their life.

In free-range broiler systems, the chickens are given continuous access to an outdoor range during the daytime and sheds where they are housed at night. Free-range chickens grow more slowly than intensive chickens. Free range poultry production requires that the poultry have access to the outside.

In some cases this means, the poultry are raised on pasture, enabling the poultry to move around, forage for their natural diet and live in cleaner conditions than those in batteries. In some farms, the manure from free range poultry can be used to benefit crops.

ADVERTISEMENTS:

The benefits are also a reduced growth rate and opportunities for natural behaviour such as pecking, scratching, foraging and exercise outdoors, as well as fresh air and daylight. As they grow slower and have opportunities for exercise, free-range chickens have better leg and heart health and a much higher quality of life.

Finding suitable land with adequate drainage to minimize worms and coccidian oocysts, suitable protection from prevailing winds, good ventilation, access and protection from predators can be difficult. Excess heat, cold or damp can have a harmful effect on the animals and their productivity.

Unlike battery farms, free range farmers have little control over the food their animals come across which can lead to unreliable productivity. Diseases are common and the animals are vulnerable to predators. In South-East Asia, a lack of disease control in free range farming has been associated with outbreaks of Avian influenza. Therefore, for commercial purposes free range culture method is not suitable.

Way # 2. Indoor or Intensive Method:

In this method chickens are kept indoors but with more space (around 12 to 14 birds per square metre). They have a richer environment, for example, with natural light or straw bales that encourage foraging and perching. The benefits of indoor systems are higher welfare with less crowding and more opportunities for natural behaviour. Intensive or indoor system includes two types — (A) Battery cage system and (B) Deep litter system.

ADVERTISEMENTS:

(A) Battery Cage System:

In this system batteries of cages are placed one upon another providing all amenities to the birds. This is the most intensive type of poultry farming and is useful to those with limited floor space. This type of farming is suitable for commercial egg farming (layer farming).

In this system hen is confined to a cage just large enough to permit very limited movement and allow her to stand and sit comfortably.

(B) Deep Litter System:

ADVERTISEMENTS:

In this system poultry birds are kept in large pens up to 250 birds each on floor covered with litters like straw, sawdust or leaves up to a depth of 8-12 inches. This system is used mainly for farming broilers. Farmers with sufficient space opt for this type of culture, because no cage and floor system is possible here.

Modern and well-established Indoor with higher welfare scientific practices should be used to obtain maximum economic benefits from poultry farming. It is necessary to obtain training/experience in layer farming before starting a farm. One has to stay on the farm for constant supervision.

Some of the major norms and recommended practices are given below:

(i) Preparation for Poultry Housing:

At the onset one has to decide whether he will start poultry farming for broiler or layer. Accordingly preparations will have to be made. In both the cases some preparations are common.

(ii) Selection of Poultry Site:

Well-raised land should be selected for poultry sheds. Land with hard rock or murram is more suitable, so that water logging and flooding near the sheds can be avoided. Separate sheds for growers and layers is recommended. Adequate facility for water, electricity, approach to road, supply of chicks, feed, veterinary aid and nearness to market for sale of cull birds and eggs should be ensured.

(iii) Construction of the Sheds:

Construction of the sheds should be in such a way that the end walls face East-West direction and the side walls face North-South direction, so that rain water cannot enter the sheds. 3 to 4 feet overhanging of the roof is recommended to avoid entry of rainwater inside the shed. The plinth of the shed should be at least one foot above the ground level.

ADVERTISEMENTS:

At least 50 feet distance between two sheds in the same sector and about 150 ft between growing and laying sector is recommended. Adequate light, ventilation and comfortable housing conditions during all seasons (cool in summer and warm in winter) are prime objectives.

Construction of sheds should be in such a way that predators (cats/dogs/snakes) will not get entry into the shed. Rat proof civil structures may be constructed to avoid entry of rats. The shed should be kept clean and free from flies/mosquitoes, etc. Adequate floor space per bird is to be provided.

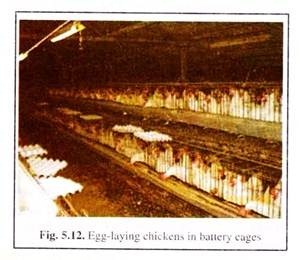

Construction of Battery Cages for Egg-Laying Chickens:

In egg-producing farms, birds are typically housed in rows of battery cages (Fig. 5.12). The usual floor space is 14 x 16 feet and the height is 1.5 feet for each cage. Many small cages can be assembled together. Usually these are multistoried.

One cage could be accommodated with approximately 100 birds. In recent years the recommendation is 67 to 86 square inch space per bird, which is about 9 inches by 9 inches. The whole set of cages are placed under a well-built roof. The floor is made up of strong galvanized wire set at a slope from back to front, so that the laid eggs roll out of the cage to a receiving gutter kept at the front side. Underneath is a tray for droppings.

Food and water containers are kept outside the cage. Environmental conditions are automatically controlled, including light duration, which mimics summer day length. This stimulates the birds to continue to lay eggs all year round.

Normally, significant egg production occurs only in the warmer months. In egg- producing farms, cages allow for more birds per unit area, and this allows for greater productivity and lower space and food costs, with more efforts put into egg-laying. Critics argue that year-round egg production stresses the birds more than normal seasonal production.

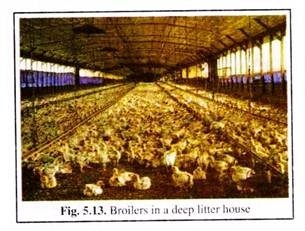

Construction of Deep Litter Cages for Broilers:

The term deep litter may be defined as the accumulation of the material used for litter with poultry manure until it reaches a depth of 8 to 12 inches. In this system poultry birds are kept in large pens (Fig. 5.13). On an average 100 birds can be accommodated in a pen of 25 x 20 feet size, i.e., 5 square feet per bird in climate-controlled housing.

In larger pens accommodation of maximum 250 birds is recommended. The floor is covered with dry litters like straw, sawdust, rice hulls or leaves up to a depth of 8-12 inches. This system is used mainly for farming meat chickens, commonly called broilers. Farmers with sufficient space opts for this type of culture, because cage and floor system is not possible here.

Maintenance of Poultry:

Poultry producers routinely use nationally approved medications, such as antibiotics, in feed or drinking water to treat disease or to prevent disease outbreaks arising from overcrowded or unsanitary conditions. Some approved medications for improved feed utilization may be applied. In advanced countries law prohibits the use of hormones or steroids in poultry production.

After every batch of growers or when culled birds are disposed of, the dirty litter material and manure should be removed, walls and floors should be cleaned, whitewashed with lime and disinfected with 0,5% malathion or other recommended insecticide spray.

If deep litter system is followed, always use dry and clean litter material (sawdust, paddy husk, etc.). Spread 4 -inch layer of litter on the floor, keep clean, disinfect brooding, feeding and watering equipment’s and then introduce chicks in the house.

The litter material should always be kept loose and dry. Stir the litter twice a week. Any wet litter, droppings, etc. should be removed and replaced with fresh/clean dry litter. If cage system is followed, ensure that droppings are spread with lime powder or 10% malathion spray twice a month to prevent menace of flies. The droppings under the cage can be removed after 6 months.

Modern poultry farming is very efficient and allows meat and eggs to be available to the consumer in all seasons at a lower cost than free range production and the poultry have no exposure to predators.

Debeaking:

The cage environment of egg producing does not permit birds to roam. The closeness of chickens to one another frequently causes cannibalism. Cannibalism is controlled by debeaking (removing a portion of the bird’s beak with a hot blade so the bird cannot effectively peck).

Osteoporosis:

Another condition that can occur in prolific egg laying breeds is osteoporosis. This is caused from year-round rather than seasonal egg production and results in chickens whose legs cannot support the body and so can no longer walk.

During egg production, large amounts of calcium are transferred from bones to create egg shell. Although dietary calcium levels are adequate, absorption of dietary calcium is not always sufficient to fully replenish bone calcium.

In intensive broiler sheds, the air can become highly polluted with ammonia from the droppings. This can damage the chickens’ eyes and respiratory systems and can cause painful burns on their legs (called hock burns) and feet. Chickens bred for fast growth have a high rate of leg deformities because they cannot support their increased body weight.

As they cannot move easily, the chickens are unable to adjust their environment to avoid heat, cold or dirt as they would have in natural conditions. The added weight and overcrowding also puts pressure on their hearts and lungs. In the U.K., up to 19 million chickens die each year in their sheds from heart failure.