The following points highlight the four important types of hatchery. The types are: 1. Traditional Method using Hatching Hapa 2. Earthen Pot Hatchery 3. Glass Jar Hatchery 4. Chinese Hatchery.

Type # 1. Traditional Method using Hatching Hapa:

(a) Hatching Hapa:

It is a traditional net enclosure with the inner net being smaller than the outer one (Fig. 6.23). The outer net consists of a fine mesh (0.5 mm) seive-cloth tank about 2 x 1 x 1 m in dimension, while the inner chamber, made of the same material, has a mesh size of 2.0 – 2.5 mm. The whole device is placed in a protected water body where the water is well oxygenated. The fertilised eggs are evenly spread in the inner hapa.

The hatched larvae fall or pass through the larger meshes of the inner hapa and are retained by the outer hapa as the small meshes of the outer hapa prevent them from escaping. After hatching of the eggs get completed, the inner hapa is removed together with the dead eggs, egg shells and other debris to prevent deterioration of the water quality within the hapa.

(b) Hatching Pits:

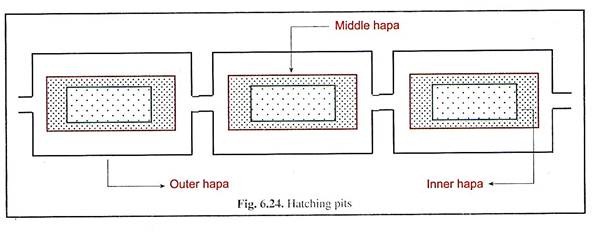

Besides the above, hatching pits are also used. Hatching pits are a series of pits located very close to the breeding ground. The size of the pit is 8 feet x 4 feet x 2 feet. Several pits are interconnected (Fig. 6.24), so as to allow the water to flow from one pit to another.

In each pit, 3 layers of cloth tanks or hapas of different dimensions are tied. The outer-most cloth tank is about 6 feet x 3 feet x 1½ feet in size and is made up of cheap cloth. For support 2 bamboo poles are fixed to which these cloth tanks are tied.

ADVERTISEMENTS:

The middle tank is smaller, 5 feet x 2½ foot x 1 feet in size and made up of mosquito cotton cloth with round meshes. The inner most tank is 4 feet x 2 feet x ¾ foot in size, having bigger mesh size.

Hatching of Eggs:

The eggs collected from rivers contain not only the eggs of major carps, but a mixture of eggs of several types of fishes and also certain larvae of insects, crustaceans, etc. The eggs, thus, before transferring to the hatching pits are subjected to sieving.

A sufficient number of eggs (approximately 9,00,000 to 22,00.000) should be kept in each hatching pit. Out of these, only 2.5% to 25% successfully hatch. The flowing water due to the interconnection between the hatching pits, activate the eggs to hatch. The time taken for hatching ranges from 2 to 15 hours.

ADVERTISEMENTS:

After hatching, the hatchlings being slender and small pass through the meshes of the inner hapa to the outer cloth tanks, whereas the unwanted masses like unfertilised eggs, egg shells, dead hatchlings, etc., do not pass through the meshes of inner hapa.

After about 20 hours of transference of eggs, the inner hapa along with the unwanted masses are removed and thrown out. The hatchlings when reach the size of 4-6 mm, are transferred to nursery pond.

Type # 2. Earthen Pot Hatchery:

(a) Construction:

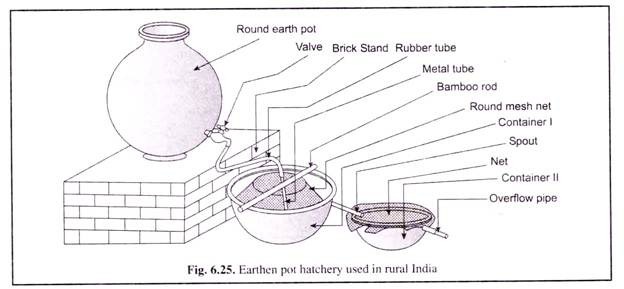

Here the principle of hatchery system is followed, where an overhead tank in the form of an earthen clay pot (Fig. 6.25) is installed on a brick stand about 2 feet in height. There are two different sized container. Container number I acts as incubator chamber; while container number II acts as a spawnary.

From the bottom of the earthen pot a valve and a rubber pipe are fitted. The other end of the rubber pipe contains a metal tube which is put into container number I. At the top of the container a round mesh sheet is placed and it is held in position by a bamboo rod. At the other end of the container I, near to the surface, a round spout is fitted.

This spout from container I opens into container II which is smaller in size than the 1st one. On the top of container II, a net is placed and to its other end, nearer to its surface, an overflowing pipe is fitted. The outer end of the pipe is covered with a small net.

(b) Working Method:

(1) At first, freshwater from a tube-well is poured into the earthen pot. The valve is regulated to maintain the water pressure entering into container I.

ADVERTISEMENTS:

(2) Fertilised eggs are then introduced into the container number I.

(3) The excess water flows out through the spout into container II and from it to the outside through the overflowing pipe.

(4) A running water condition is, thus, maintained.

(5) The water pressure is regulated in such a way, that the eggs do not pass out into the second container.

(6) When the eggs hatch, the hatchlings have a tendency to undergo vertical migration. So, it comes to the surface and the overflowing water carries it into container II.

(7) The unwanted materials such as egg shells, unfertilised eggs, deformed eggs remain behind in the 1st container.

(8) The spawns are then kept in container II for 2-3 days. It is fed externally, if necessary, and later are either introduced into the nursery ponds or sold to other farmers.

Merits and demerits of Earthen Pot Hatchery:

(a) Merits of Earthen Pot Hatchery:

(1) Cool and running water condition which is essential for hatching, is maintained.

(2) Cost of making an earthen pot hatchery is very less.

(3) Very easy process to handle.

(b) Demerits of Earthen Pot Hatchery:

(1) Earthen pot is not capable of storing a large amount of eggs.

(2) Very laborious manual process and time consuming.

(3) Handling should be done with care as pots are liable to breaking.

Type # 3. Glass Jar Hatchery:

A glass jar hatchery is a much modified set-up than the earthen pot hatchery. It is comprised of:

(a) Water supply system

(b) Breeding tanks

(c) Incubation and hatching jars, and

(d) Spawnery.

Location:

Glass jar hatchery is generally installed by the side of a water source which may be a perennial pond or a river or a water supply from a tube-well. It should be kept in a well-ventilated room with adequate light and proper drainage system.

Construction:

(a) Overhead Tank:

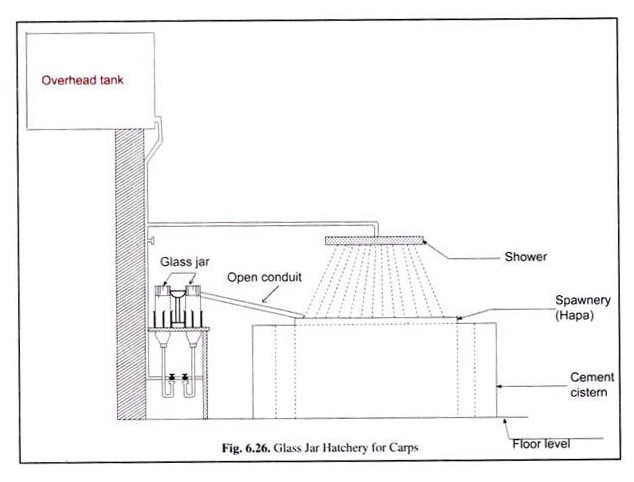

Available water from the source is pumped up into an overhead tank (Fig. 6.26), which is installed above a brick wall. If water is drawn from a river, then a desilting tank should be provided. A fine meshed wire-netting is provided in the pump system.

This helps to prevent the entry of organisms commonly present in the water of river and pond. A deep tube-well is of much facility as it provides clean water. The tube-well should be installed in an arsenic-free area.

(b) Breeding Tank:

As hatchery is a self-contained unit, it generally contains a breeding tank with arrangement for overhead showers. This tank is provided for spawning the fish. An outlet is present in each tank, for draining the excess water.

A breeding tank is made of 1.8 m x 0.9 m x 0.9 m in dimensions. Generally, in a farm there are 2-3 breeding tanks where 2-4 breeding hapas can be fixed at a time. However, the number of breeding tanks in a hatchery depends on the spawn production target.

In a hatchery where there is no provision of breeding tanks, the operation is undertaken in hapas fixed in ponds and the fertilised eggs are released into the glass jar for incubation and hatching. Sometimes, the spawnery itself can be used as a breeding tank.

(c) Incubation and Hatching Jars:

There are different types of incubation and hatching jars used, ranging from the glass jars, synthetic jars to Zong jars, with temperature controlled water supplies.

(i) Glass Jars:

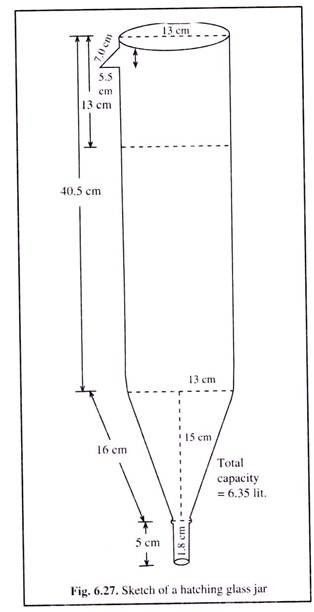

Glass jars are conical in shape. They are open at the top and gradually tapering towards the bottom. The various measurements of the jar are given in Fig. 6.27.

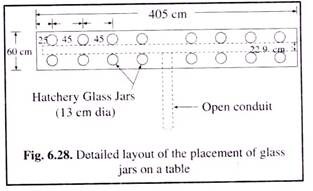

The glass jars are set up vertically through the circular holes made in a wooden table (Fig. 6.28). The table is of 4.05 m x 0.6 m with a height of 0.9 metre. The detailed plan for the sequential placement of jars on the table is given in Fig. 6.28. The jars are fitted in two rows at a gap of 22.9 cm. They are kept in a vertical position with the help of clamps (Fig. 6.26).

The top of the jar is fitted with a galvanised iron ring with a beak (Fig. 6.27). It serves as an outlet for water coming out of the jar. The jars are connected with rubber tubings at the bottom with respective taps (Fig. 6.26).

Each glass jar has a capacity of 6.35 litres and can accommodate 50,000 carp eggs at a time. A long open galvanised conduit (Fig. 6.26 and 6.28) is fitted in such a way that the overflowing water from each jar passes into it and flows down to the spawnary.

(ii) Zug Jars:

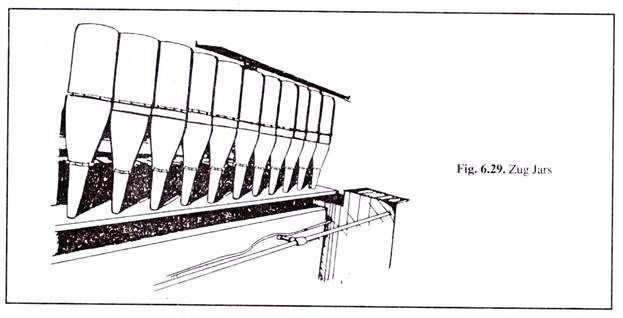

The Zug jars, name after Zug (Switzerland) where they were first used, are large (60-70 cm in height and 15-20 cm in diameter), inverted bottles, with open tops and narrow bottoms.

In a hatchery they are installed vertically in a series, with the narrow neck directed downwards attached to the water lines with suitable taps (Fig. 6.29). Water is supplied from below and the outlet is at the top. The Zug jars have a capacity of 6-8 litres and can carry about 1-5 litres of eggs.

(iii) Mac Donald or Chase Jars:

Mac Donald Jars are similar to the Zug jars. It is cylindrical in shape (40-50 cm in height) with a circular bottom for the water supply and the flow of water in the jar keeps the eggs rotating slowly.

(iv) Farm Fabricated Incubation Funnels:

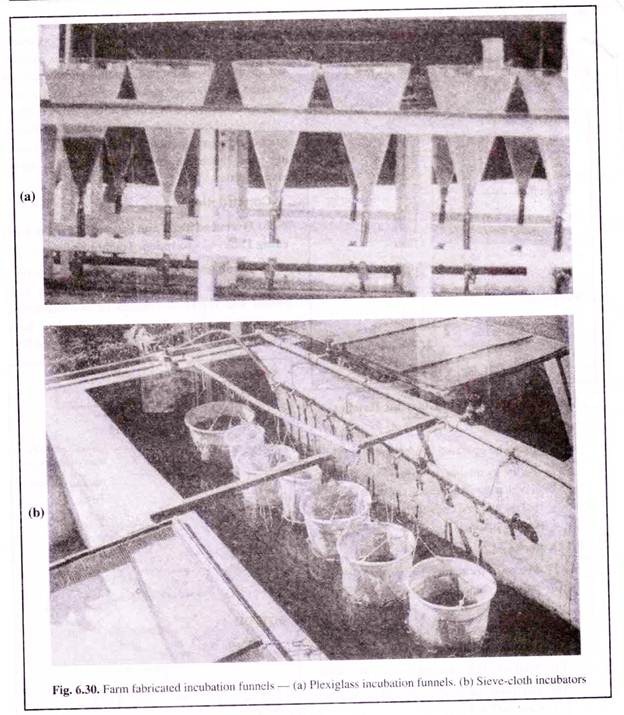

They are made of plexiglass or fibre glass, in any required dimension, and are widely used. Israeli farmers use plexiglass incubation funnels (Fig. 6.30a) of 80 cm long and 60 cm in diameter at the upper rim. Water is supplied from a bottom inlet, while water overflows from an outlet at the top.

This overflowing water is used for collecting the hatchlings. Each such funnel can be used to hatch about 1,75,000 carp eggs. Woynarovich and Horrath (1980) illustrated a number of designs of incubation funnels that can easily be made with plastic and seive-cloth (Fig. 6.30b) materials, with some sprinkler-type water inlet.

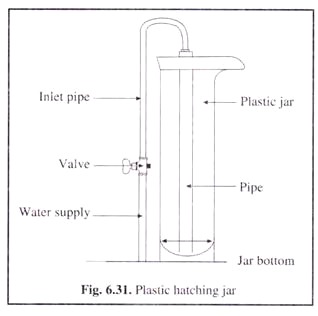

(v) Plastic Jars:

These jars are made of low density polythene. The upper part has a diameter of 440 mm, and 625 mm height, with a capacity of 40 litres. Each jar has independent control valve. For effective use, an inner egg container is used for separating the egg shells after hatching.

Hatching jar with water supply from above (Fig. 6.31) is also in use when the inlet pipe from above extends deep into the bottle.

(d) Spawnery:

The spawnery is a hapa of synthetic material which is fitted on a frame, placed inside a cemented cistern or tank. The height of the hapa is slightly more than that of the cemented cistern to prevent the hatchlings from being carried away along with the overflowing water from the cistern. An overhead shower (Fig. 6.26) is provided to spray water over the developing hatchlings in the hapa.

The cemented cistern of the spawnery measures 1.8 m x 0.9 m x 0.9 m and the hapa measures 1.65 m x 0.8 m x 1.0 m. It can accommodate about 10 lakh spawns at a time.

Working Method:

Water, either from adjacent ponds or rivers or from ground water, is pumped into the overhead tank. From the overhead tank water flows into the incubation jars and spawnery (Fig. 6.26).

The water hardened eggs (about 50,000) are then slowly released into each incubation jar and the water pressure is regulated during incubation, so that the eggs are stirred gently without being split or overflowing.

A flow of600-800 ml per minute is sufficient to keep the carp eggs in circulation inside the jar. Water enters into the incubation jars either from the bottom (Fig. 6.26) or from above through a pipe which opens at the bottom (Fig. 6.31).

After the eggs are hatched, the hatchlings have a tendency of vertical migration, As a result they come up to the surface and pass through the outlet along with the overflowing water into the open conduit leading to the spawnery. The rate of flow of water in the jars at this time is slightly increased after the completion of hatching to facilitate speedy escape of hatchlings.

Dead eggs, unfertilised eggs, egg shells, abnormal and dead hatchlings are left behind in the jars which are subsequently removed by disconnecting the glass or incubation jar from the tap.

In the spawnery, the water is sprayed continuously for about 3 days until the fry are ready for stocking.

Merits and Demerits of Glass Jar Hatchery:

(a) Merits:

(1) It can be operated in a compact area.

(2) As the incubation jars are transparent, the developing embryos can be seen with the naked eye and appropriate rectifications can be made.

(b) Demerits:

(1) In case of incubation jars made of glass is liable to damage and cannot be shifted to different places.

(2) Temperature control system is not provided.

(3) Additional air circulation is not provided.

(4) Hatching success is less than that of Chinese hatchery.

(5) Damages of eggs from the glass jars during transfer may take place.

Type # 4. Chinese Hatchery (Eco-Hatchery):

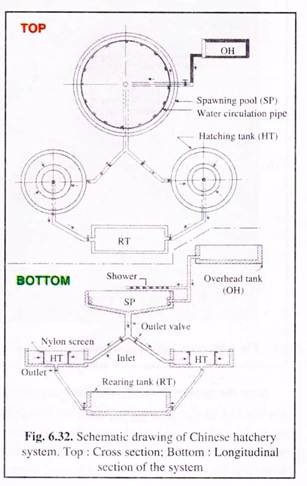

Chinese investigators have developed circular hatching tanks, in which water is in a continuous state of flow in a circular direction. This is popularly known as Chinese hatchery system.

This system, within a small space, simulated some aspects of riverine environment and has proved itself a very successful method of breeding carps where commercial production of carp seed is required. The Chinese hatchery system comprises an overhead tank, spawning pool, incubation or hatching tank and spawn rearing tank.

Construction:

(a) Overhead Tank and Spawning Pool or Breeding Tank:

Descriptions of these are given earlier.

(b) Incubation or Hatching Tank:

Hatching tank is circular in shape and is constructed with cement and bricks. It consists of two concentric circular tanks (Fig. 6.32). The two chambers have inside diameters of 1.6 m and 5.0 m. A water of 0.92 to 1.0 m depth is maintained by an outlet pipe fitted in the middle of the inner circular tank.

The inner circular tank has gaps on its body, through which water passes into the inner space. This gives the shape of a double doughnut. One wall of the double doughnut lies at the periphery, while the other at the inner end that lies surrounding the outlet (Fig. 6.33).

Prior to the introduction of eggs, the inner wall or chamber is separated from the outer by a fine nylon screen which is stretched and fitted on an iron frame. A rubber belt is fastened very tightly to seal the compartment.

The floor of the outer compartment has a number of diagonally fitted pipes which face in one direction, thereby providing the circulation of water (clockwise) when the taps are opened.

The water-holding capacity of the incubation tanks is about 7 to 10 m3 and has a relative egg density carrying capacity of about 68 x 104 m3 to 70 x 104 m3. The water flow is maintained at 2251/min throughout the operation except during the period of hatching, when it is maintained at 250 1/min.

(c) Spawning Tank:

The hatching tank acts as the spawning tank after hatching of the eggs and the water flow is maintained at an optimum level. The hatchlings are reared here for 3 days.

Working Principle:

After pituitary injection, the male and female brooders are released into the spawning pool. The hatchery is made ready prior to the introduction of eggs and the level of water is maintained by adjusting the outlet pipe.

The eggs may be brought mechanically from the spawning pool or may be drained directly into the outer chamber of the hatchery through underground pipe system (Fig. 6.32).

The eggs in the outer chamber are kept in circulating condition due to the circulation of water made possible by the circular arrangement of pipes fitted on the floor. Continuous water circulation in the incubation tank helps to maintain a high oxygen level of the water and churning of eggs throughout.

The chosen flow rate of water helps to maintain the required temperature necessary for high hatching success. The flow rate was increased during hatching because of the high oxygen demand during the process. At about 11 to 12 hours after fertilisation, hatching of the embryo starts and gets completed within 4 hours.

After all the eggs have hatched, the flow rate of water was decreased. To avoid bacterial disintegration the eggs shells, unfertilised eggs, dead hatchlings, etc. are removed periodically from the incubation chamber.

This is done either by siphoning or by dipping a jute rope with a weight into the outer chamber. The circulating egg shells get attached to the jute rope, which is periodically taken out; the egg shells removed and the rope is again put into the outer chamber, till nearly all the egg shells are removed.

Some unfertilised eggs remain behind in the hatcheries and these are the focus for fungal infection caused by Saprolegnia. A common method of controlling fungal disease in the incubator is by the application of malachite green at a concentration of 0.02 g/litre of water for about 20-25 minutes after stopping the flow of water. When the flow is resumed, the chemical is washed out from the incubator.

Merits and Demerits of Chinese Hatchery:

(a) Merits:

(1) Chinese hatchery ensures a high hatching success (98%), as good and clean water replacement is possible.

(2) Water flow and thus the temperature can be maintained during hatching.

(3) The Chinese hatchery can be directly connected to the breeding pool on one hand and to the nursery pond on the other. Therefore, it ensures less damage of fertilised eggs and spawns at the time of transfer.

(4) It minimises the labour cost.

(5) Much larger quantity of eggs can be accommodated.

(b) Demerits:

(1) Due to the absence of proper spawnery, total removal of shells, unhatched eggs and dead spawns and larvae are not possible.

(2) Initial cost of the set-up is very high.

(3) Proper technical application has to be maintained regarding fitting of pipes, direction and amount of water flow.

Physico-Chemical Nature of Water/Water Quality Parameters at the Time of Hatching:

The water quality changes are fairly evident during the development of eggs and these are regulated to ensure greater hatching success in the glass and Chinese hatchery.

1) In case of Indian carp eggs a water temperature of 29.3°C results in mass hatching which starts about 11 to 12 hours after fertilisation and gets completed within 4 hours (Jana et al., 1985). A slight decline of water temperature to 28.65°C and 28.7°C delayed mass hatching by 1 and 3 hours, respectively.

2) The oxygen amount ranging from 6 to 7.2 mg/ litre is found to be adequate to account for hatching success. It has been reported (Garside, 1959) that reduced oxygen tension retards development of fish embryo, while water rich in oxygen accelerates the process (Kinne and Kinne, 1962).

3) The total hardness and biocarbonate of hatching water increases markedly after the transfer of eggs. This marked rise in hatchery water after egg transfer might be due to liberation of Ca++ and Mg++ from egg mass.

4) Free carbon-dioxide of the hatchery water rises gradually as the length of the embryonic development advances, because of respiratory activity of the fertilised eggs and larvae. This, thus results in the decline of pH.

5) The nitrogenous compounds like ammonia, nitrate and nitrite increase at the time of hatching and these compounds are released by the developing embryos.

6) The phosphate level is greatly reduced during hatching period but tended to rise afterwards. It is due to food reserve in yolk that gets exhausted during hatching, and developing embryos utilise phosphate from the external water medium for their bone formation.

The manipulation of the above limnological conditions would thus ensure an increase in the carrying capacity of the seed rearing system.