The following points highlight the seventeen important by-products of fish. The by-products are: 1. Fish Liver Oil 2. Fish Body Oil 3. Fish Meal 4. Fish Manure and Guano 5. Fish Flour 6. Fish Silage 7. Fish Solubles 8. Fish Sausage and Ham 9. Fish Macaroni 10. Fish Biscuits 11. Fish Glue 12. Isinglass 13.Fish Skin 14. Artificial Pearls 15. Fish Fins 16. Fish Roe and Fish Caviar 17. Medicinal Products.

By-Product # 1. Fish Liver Oil:

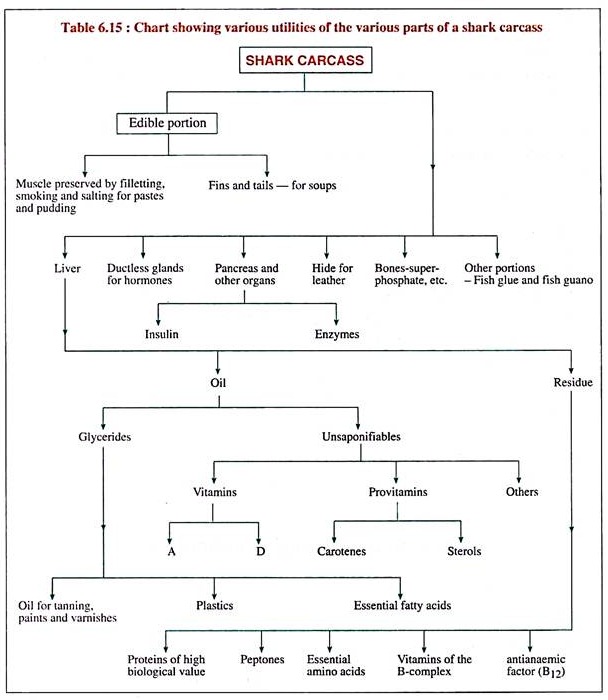

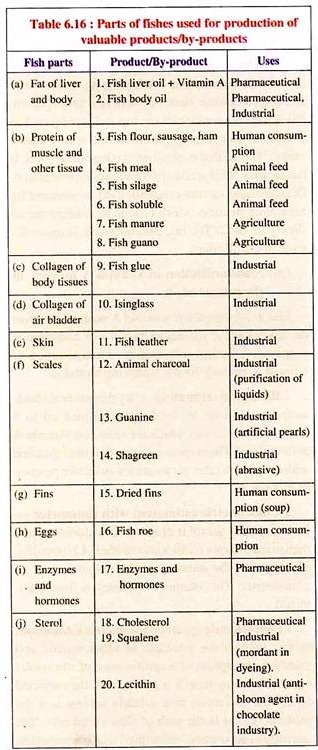

Fish liver oil is one of the most important by-products of fish. Liver, which is a part of the offal discard during dressing of landed fish, is the storehouse of glycogen and fat along with Vitamins A and D. This property of fish livers of certain fishes like Cod, Shark, Ray, Halibut, Tuna, etc. has rendered it of immense commercial value of providing highly medicinal ‘liver oil’.

(a) Composition of fish liver oil:

ADVERTISEMENTS:

Water — 20% to 36%

Proteins — 5% to 10%

Fats — 55% to 75% (Unsaturated fatty acids higher in concentration than saturated ones).

As fat carries with it high concentration of Vitamins A and D, the fat of fish liver is the source of vitamins A and D rich liver oil. However, the concentration of vitamin A and fat in the liver varies from fish to fish and from season to season.

ADVERTISEMENTS:

Halibut (Psettodes sp.) and tuna (Thunnus sp.) liver have low fat but high vitamin A content (50,000 to 3,00,0001.U. per gram), while cod (Gadus sp.) liver is rich in fat but poor in vitamin A (1000-3000 I.U. per gram).

Vitamins A and D present in fish liver oil is in proportion most suitable for human needs, as it has medicinal use in the form of prophylactic and curative.

(b) Method of extraction of fish liver oil:

ADVERTISEMENTS:

For extraction of quality liver oil it is essential that the liver of fishes be in good condition (either fresh or properly preserved). This is to guard the protein and fat rather than vitamin A content which is very stable.

Depending upon the method of extraction used, fish liver oils are of the following grades:

(1) Crude oil used for burning,

(2) High quality technical grade oil,

(3) Intermediate grade oil, and

(4) Edible oil for medicinal use.

The first three grades of oil are produced from diseased or discoloured livers while the last one is produced from fresh or suitably preserved livers.

(i) Oil extraction:

Some popularly used methods of oil extraction are given below:

ADVERTISEMENTS:

(1) By autofermentation:

Fish livers are first chopped into small pieces and exposed to sun in earthen pots for several days, so that it undergoes decomposition. As it undergoes decomposition, the oil that is released is collected. This oil is crude and used for burning lamps in curing yards.

(2) By boiling:

Chopped livers are boiled with sufficient quantity of water. The released oil is then decanted off easily. Although this method is simple, the yield, however, is moderate as all the oil is not extracted from liver. This method is generally followed in small scale industries.

(3) By steaming:

Minced livers of fishes such as cod (which has high oil content) are steamed at a temperature of 85-90°C under a pressure of 2 kg/sq. cm. The liver cells disintegrate and the oil is collected from the top layer. This method is good for operation while on board of fishing vessels or trawlers, where steam is readily available.

(4) By chemical digestion:

Chemical digestion is done by the following three methods:

Aquacide digestion:

Aquacide is a patented mixture of sodium bicarbonate and paraldehyde. When fresh liver is mixed with it, it partly denatures the protein and yields a pulp. The pulp is stirred with warm water as it is passed through a series of tanks or cylinders. This gives rise to an emulsion of water and released oil. As soon as the emulsion breaks, the oil floats on the top from where it is collected.

Alkali digestion:

Digestion of proteins in the liver with alkali has proved to be the most successful method. The livers of halibut, tuna and some sharks, which are relatively poor in oil but high in vitamin A potency, are processed in this manner. In this case, the oil is held strongly by proteins and is not totally released by steaming or boiling.

Minced liver is mixed with dilute caustic soda (1-2% by weight) or sodium bicarbonate (2-5% by weight). It is then steamed at 82-88°C with constant stirring. The pulp is then centrifuged and the supernatant oil is collected.

Enzyme-alkali digestion:

This chemical digestion is a modified version of the above, where alkali (sodium bicarbonate) is added after the chopped liver is treated with an enzyme (pepsin). As pepsin acts best in an acidic medium, HC1 is added to the mixture.

At first the chopped liver is brought to pH level of 1.2 to 1.5 by the addition of HCl. Then commercial pepsin (0.5% by weight of the liver) is mixed with the pulp and digested at 43-49°C. The pH is then raised to about 9.0 by the addition of sodium bicarbonate and the temperature is increased to 80°C. After complete digestion, the oil that has gathered at the top is collected.

(5) By solvent extraction:

This is an advanced and expensive process although the yield is higher. This involves solvent extraction plant/equipment and solvents, like ethylene dichloride, solvent ether, chloroform, light petroleum, etc.

In this method, at first the minced liver is dehydrated with the application of an anhydrous salt, generally sodium sulphate. When the moisture has been removed, the pulp thus formed is mixed with the solvent (preferably ethylene dichloride) and put to extraction process.

After distillation the oil is separated out. Any free fatty acid present in the liver is removed during refinement of the oil. The solvent extracted oil is darker in colour and has a higher viscosity.

(ii) Refinement of liver oil:

The oil after collection from the above methods is left to stand, so that water and any particulate matter present in it settles down. Oil is then removed from the top and is subjected to filtration, centrifuging, or treatment with Fuller’s earth. The oil that is obtained is congealing oil.

It has stearine (triglyceride of stearic acid) present in it. Destearinated or non-congealing oil is obtained by separating stearine, which is done by cooling the oil slowly to 10°C. The oil, thus obtained, is again filtered in a chill room.

(iii) Standardisation of vitamin A potency in the extracted oil:

Due to its richness in vitamin A content, the liver oil has immense medicinal value.

For commercial purposes, it is thus subjected to standardisation of vitamin A potency by the following methods:

1. Biological estimation:

By this method standardisation is done by feeding the refined oil to 5 weeks old albino rats which are raised on vitamin A deficient diet. The response in growth is then matched with the growth rates of rats grown on known potency of vitamin A.

2. Colorimetric estimation with tintometer:

In this method the oil is dissolved in chloroform and then to it antimony trichloride is added. A blue colour develops and the intensity of this colour is read on a tintometer. The vitamin A potency is thus determined.

3. Photoelectric spectrophotometry estimation:

In this method the principle of characteristic and selective absorption of a certain zone of ultraviolet region of the spectrum is used. For this, the extracted oil is first dissolved in a suitable solvent and the solution is kept in the path of ultra violet rays. The intensity of absorption is measured with photoelectric unit and can be read on its galvanometer.

(c) Uses of fish liver oil:

Fish liver oil has the following uses:

(1) Crude liver oil is used for burning purposes or making lights in curing yards by fishermen.

(2) Fish liver oil because of its high vitamin A and D contents can cure or prevent occurrence of disease caused by the deficiency in the body of these two vitamins, such as rickets, xeropthalmia, impaired vision and eye defects, abnormalities of skin, mucous membranes and vertebrae.

(3) When taken orally it will ensure good growth of bone and teeth and will develop more resistance to counter bacterial attack.

(4) The stearin obtained by chi I ling the oil is used to make soaps of inferior grade and in leather curing.

(5) Inferior pharmaceutical grades are used in animal and poultry feeds.

(6) The volatile fraction of the liver oil, distilled at 250°C is toxic to bacteria and fungi.

(7) Alkoxyglycerol present in shark liver oil provides a unique immune supporting nutritional effect.

(8) Squalene present in certain shark liver oil as a constituent of the unsaponifiable fraction of fish oil, is used as a mordant in the dyeing of synthetic fibres.

(9) Lecithin, present in high concentration in dogfish liver oil (and in the oil of fish eggs) is used as a wetting and an anti-bloom agent in the chocolate industry.

By-Product # 2. Fish Body Oil:

Fish body oil is the oil obtained from the entire body of fishes like Herring, Sardine, Salmon, Mackerel, Anchovy, etc. It is also extracted from offal and other wastes discarded from canneries or curing yards. Fatty fishes like Sardine yield more oil than non-fatty fishes. However, on an average about half kg of fish body oil can be obtained from five kg of fishes.

Fish body oil varies according to season, sex, size, age, nature of food and the locality from which it is caught. It has been observed that the body oil content in mackerel rises to a maximum in October- November and falls thereafter.

Fish body oil substantially differs from fish liver oil. Fish body oil is poor in vitamins A and D contents and has less unsaponifiable matter as compared to fish liver oil. The presence of various proportions of the glycerides of fatty acids (both saturated and unsaturated groups) has resulted in various uses of fish body oil.

Methods of fish body oil extraction:

There are two methods of extraction of fish body oil:

(i) Dry method and

(ii) Wet method.

(i) Dry method of extraction:

This method of extraction is used in fishes with low body oil content and the oil recovery is less than the wet process. The fishes are grounded in a grinder, cooked (with constant stirring) and pressed to recover the oil.

(ii) Wet method of extraction:

The wet method is employed for obtaining body oil in fishes such as Oil Sardine (Sardinella longiceps), which are rich in oil content. In the wet method, the fishes are crushed to a pulp and cooked with steam in a continuous vertical cylindrical cooker. The cooked material is then pressed and a mixture of oil and stick-water (pressed liquid of fish soluble) are collected into setting tanks or are centrifuged to separate the oil.

Refinement of fish body oil:

In both the above methods of oil extraction the residue (after pressing) is processed as a by-product — the fish meal. The oil thus collected after pressing contains protein debris and lots of other impurities such as water soluble and non-fatty acids of the body tissues.

The pressed liquid is first filtered and then subjected to various refinement processes such as:

(1) To neutralise the acids it is treated with caustic soda.

(2) To remove bad odour, the liquid is treated with super-heated steam and sodium carboante.

(3) To bleach the unwanted dark colouration, it is subjected to aeration.

(4) To remove moisture, it is heated to a temperature Of 105°C.

(5) To remove any stearine content, it is subjected to refrigeration.

Uses of fish body oil:

(1) After various refinement processes (as above), the better grades of body oils thus formed, are used for edible purposes.

(2) The fish body oil of high iodine value is very suitable for manufacture of paints and varnishes, as it is a drying oil.

(3) It is used in dressing of leather and tanning of skin.

(4) Body oil of low iodine value are generally preferred for making solid fats, such as margarine and lard (refined fat from the abdomen of a pig) substitutes.

(5) It is used in the manufacture of laundry soap and cheaper grades of toilet soap, insecticidal soap, etc.

(6) It is used in steel and iron industry for tempering of steel, concentration of low grade iron ores, etc.

(7) Due to the presence of vitamins A and D, the fish body oil is used for medicinal purposes, for animal and poultry feed and in aquaculture practices.

(8) It is used in the manufacture of chemicals such as alkyl halides, silicons and quaternary ammonium salts.

(9) It is used in the manufacture of cosmetics, lubricants, candles and cutting oils.

(10) Fish oil formulations when sprayed on citrus trees have proved effective as fungicide.

(11) It is used in the manufacture of printing inks, water-proofer preparations, plastics and linoleum (a substitute for rubber).

(12) Body oil is used for smearing the surface of boats for longer preservation.

By-Product # 3. Fish Meal:

Fish meal is the next most important product after fish liver and body oil. It is a preparation where the body of fresh fish is ground, cooked and dried. It is a highly nutritive product and is an excellent poultry and animal feed, which increases egg and milk production.

The nutritive value of fish meal depends upon:

(1) Type of fish used (low fat and salt content to be used),

(2) The state of freshness of fish,

(3) Season of landing and

(4) Manner of preparation.

Chemical composition:

Moisture —6-12% (Moisture content is greater in lean fish than in fat fish).

Proteins — 55-70% (The protein of fish meal is of high digestibility coefficient and contains all the essential amino acids).

Oil/fat -2-15%.

Minerals — 10-20% (calcium 5%, phosphorous 4% and iodine).

Vitamins — Very rich in vitamins A, B, B12, D, K and E.

Raw material:

The raw materials include fishes such as sardines, mackerels, ribbon fish, silver bellies and other fishes. Sharks and rays yield superior quality of fish meal. Fish meal is also obtained as a by-product of the canneries and fish oil industries.

Preparation of fish meal:

For manufacturing of fish meal the following methods are employed.

(a) Preparation for small scale production:

The fish is first minced and then cooked. To remove moisture, the cooked mass is pressed in screw presses. The cake thus produced is dried in the sun, or in flame driers in which the material is exposed to high temperature or generally in steam-jacketed drums under partial vacuum.

(b) Preparation for large scale production:

Here huge amount of raw material is used, that includes.

(i) Entire landed fish of poor food value,

(ii) Wastes from filleting plants (of canneries) and

(iii) Curing yards.

The raw materials, thus collected, are ground well to crush bone and flesh. The minced mass is then heated in steam, either by external application of steam (dry process) or by pressure-steaming through the minced mass (wet process).

Hydraulically operated pressing is then done and after extraction of oil and water, dry cakes are ready for sac filling and marketing. Fish meal is generally packed in gunny or coir bags, which are insect and vermin proof. Storage, if done in tin containers, is done under an atmosphere of nitrogen and with soldered lids.

Use of fish meal:

(1) Fish meal being a highly nutritive product (it contains all the essential amino acids) makes it an excellent poultry and animal feed which is practically good for all classes of livestock. By its use milk and egg production gets increased.

(2) As fish meal contains calcium, phosphorus, iodine and rich variety of vitamins, it is important for growing catties, for it promotes building of tissue and bone.

(3) Trash fish meal mixed with rice bran and vitamins, forms an excellent feed in aqua- culture.

By-Product # 4. Fish Manure and Guano:

Fish manure and guano are inferior quality of fish meal. It is not fit for animal consumption. Fish manure is a by-product of the curing yards, fish glue industries and oil extraction plants, where trash or spoilt fishes have been employed. Mackerel, horse mackerel, sardine, etc., which are spoilt and unfit for use as food is used for preparation of fish manure.

This manure has a high content of nitrogen (5-7%), phosphates about 4-6% and lime (CaO) 1-5%. For such nutrient content, fish manure is useful in raising coffee, tea and tobacco crops.

Fish guano is the by-product of the body oil extraction plant which is the dried refuse left after the oil is pressed out. Here oil bearing species such as oil sardines are used as raw material. Fish guano contains high concentration of nitrogen (8-10%) and appreciable quantities of phosphoric acid. For this, guano is several times more effective than any animal manure.

By-Product # 5. Fish Flour (Hydrolised Protein):

Fish flour is a superior quality fish meal, produced under strict control and care, and forms an ideal protein supplement for human diet, even for infants of 3-4 months old. On commercial scale, it is produced by a sophisticated solvent extraction process.

The process is complicated and is not expensive. Fish is chopped and washed. It is then boiled with dilute acetic acid at 80°C. The mass is then washed thoroughly and the water is pressed out.

This is then treated with petroleum to remove fat and also to increase its keeping quality. The mass, thus, obtained is then hydrolysed with an alkali, preferably with caustic soda (10% at 80°C). The entire mass is then liquefied when it is neutralised with acetic acid (85%). The liquid is then dried with a spray, which subsequently forms a dry, cream coloured powder.

Use of fish flour:

(1) It is considered as an ideal protein source to supplement diet for both adults and infants.

(2) It is used to enrich bakery products such as bread, biscuits, cakes and soup.

(3) As the product contains high protein (35%), it is very suitable for convalescing patients struck with malnutrition, anaemia, etc.

By-Product # 6. Fish Silage:

‘Silage’ generally means fodder converted in a cylindrical tank called ‘silo’. Fish silage is a liquid or semisolid fish meal and is a highly nutritive animal feed. It is produced by adding 3-4% of an acid to a minced fresh fish or fish offal. Generally formic acid is used but sulphuric or propionic acid can also be used.

By using these acids the pH of the mixture can be lowered to 4.0 or below. This inhibits bacterial decay. The enzymes present in the chopped fish act upon it and reduce the mixture to slurry. An antioxidant is added to prevent rancidity of fats and the liquid can be stored in a silo up to 6 months.

Fish silage is also obtained by fermentation with lactic acid bacteria in molasses. The advantage fish silage has over fish meal is that the vitamins remain unaffected to a large extent and the product is free from fishy odour. Its production is more preferred in temperate regions (Norway, Denmark, etc.) than in tropical countries.

By-Product # 7. Fish Solubles:

The residual part of the liquid which is obtained during the extraction process of fish oil is known as fish solubles. It is valued as additives to dry feeds for animals.

It is rich in protein and vitamin B-complex and has the following composition:

Water —50.0%

Protein —33.9% (all essential amino acids)

Fat —2-6%

Ash — 9.4%

Vitamin B-complex and choline.

By-Product # 8. Fish Sausage and Ham:

Fish sausages are prepared from minced fish flesh that are stuffed into a prepared intestine or similar other casings. Fish ham, on the other hand, has small pieces of solid fish meat (pieces of one square cm), mixed with pasted fish meat. In both the preparation, spices and additives are added to improve the taste, flavour and keeping quality.

Spices include salt, sugar, chillies, onion, corriander, glutamate, egg- white, hydrogenated vegitable oil, etc. Additives comprise antiseptics and antioxidants (ascorbic acid) to prevent rancidity. Colouring agents also may be added. These products are commercially manufactured in Japan, Russia and USA, and are prepared from less valuable trash fishes.

By-Product # 9. Fish Macaroni:

Macaroni is a pasta (flour and egg food preparation of Italian origin), prepared from wheat flour in the form of dried, hollow tubes. Fish macaroni is a product which is prepared from Puntius carnaticus. The fish is first minced and then mixed with tapioca or sorghum flour in equal parts.

It is then spiced with salt, chillies and tamarind. The product (paste) is extruded and dried. The product has good keeping quality, is cheap and easy to manufacture. It is manufactured on commercial scale by the Mysore Institute of India.

By-Product # 10. Fish Biscuits:

Fish biscuits are manufactured in Chile and Morocco. It is blended with biscuit mixture prior to baking.

By-Product # 11. Fish Glue:

Fish glue is a good adhesive obtained from trimmings, bones and skin of fishes belonging to order — Gadiformes (Cods, Pollack, Hakes, etc.). The raw materials are washed, chopped and steam-heated in steam-jacketed cookers.

The mass is then covered with water and to it is added small quantity of acetic acid. It is then cooked for 6-10 hours. The liquor is extracted and concentrated to form glue. The residue is dried and is used as manure.

Fish glue is used for:

(1) Smearing the backs of glued stamps and labels.

(2) Glue obtained from cod is of better quality and is used in photo-engraving.

(3) Low quality fish glue is used as adhesive for paper boxes, shoes and other things like furniture where joining is required.

By-Product # 12. Isinglass:

Isinglass is a gelatin-like material obtained from the swim bladder or air-bladder of certain fishes. When put in water, it swells up but does not dissolve in it. At high temperature it hydrolyses in water to produce strongly adhesive gelatin.

Swim bladder is a hollow sac, the outer layer is thick and fibrous, while the inner one is thin, often with a silvery lustre. The thin, inner silvery shiny layer of the air-bladder of some fishes, such as sturgeons, carps and catfishes, is used to derive isinglass.

For preparing isinglass the air-bladders are collected, washed thoroughly to remove blood and other extraneous matters. Then the outer thick and fibrous layer of the wall is separated from the inner layer, which is exclusively isinglass raw material. This is then sun-dried and marketed.

Isinglass has the following uses:

(1) Isinglass is used mainly for clarification of wine, beer and vinegar.

(2) It is used for the preparation of special grade cement and plaster.

(3) Formerly it was used as a substitute for gelatin in confectionery.

Product # 13. Fish Skin:

The skin of larger fishes is collected, soaked in brine and left for a day. On the next day it is salted and again put in brine containing 10% hydrocholoric acid. The skin is then taken out, drained and scraped on the surface, particularly to remove fine denticles present in the skin of sharks. They are then limed and tanned by the usual process.

Fish leather has various uses, such as:

(1) Natives of old age used the dried and spiny skins of Globe fishes or Porcupine fishes for making war helmets.

(2) In Japan the dried skin of Puffer fishes is inflated and used to make lanterns.

(3) Now-a-days the skins of larger fishes, such as cod, salmon, halibut, toadfish, sharks and rays are tanned and marketed as ornamental leather and can be dyed in different colours.

(4) Fish leather, particularly of sharks, is used in making shoes, wallets, bags and tobacco pouches.

(5) The skin of sharks, ray, skates are very hard and is used as an abrasive for polishing wood or metal.

(6) Suitably prepared and dyed skin of sharks providing ‘Shagreen’ issued for covering card cases, jewellery boxes, sword scabbards, etc.

By-Product # 14. Artificial Pearls:

The silvery scales of Europen cyprinid have been used for the manufacture of artificial pearls. By scrapping the scales, a glossy pigment is obtained. It is then coated on the inner surface and formed into hollow glass beads. The beads are then filled with wax.

By-Product # 15. Fish Fins:

The fins (except caudal fin) of shark are cut near the root, washed in sea water, dusted with a mixture of wood ashes and lime and dried in the sun or smoked. The cured product is crisp and brittle. In China and Philippines the shark fins are used in soup.

By-Product # 16. Fish Roe and Fish Caviar:

Roe (mass of eggs or spawn) of a number of fishes is considered as food. The protein of roe is tasteless and its digestibility co-efficient and biological value are 81 % and 88%, respectively. Roe fat is characterised by high lecithin (59%) and cholesterol (14%). Roe is a good source of vitamin B. It also has vitamins C, E and D.

Caviar is the processed and salted form of roe of any large sized fishes. The caviar of sturgeons is held in high esteem as a very delicious food and serves as an appetiser.

By-Product # 17. Medicinal Products:

(1) The pancreas of shark is very rich in insulin. Whales also provide a considerable quantity of insulin. Fish replaces catties in providing raw material for the manufacture of insulin.

(2) The large otoliths of Sciaenids are removed from the head and after rubbing and mixing them with water, are given to convalescent children suffering from rickets.

(3) Amphipnous cuchia has been considered by fisher folks as a highly medicinal fish. As soon as the fish is caught, gram flour (besan) or wheat flour is rubbed on its body, so as to wipe out all the mucous. The flour with mucous is then made into small balls and then dried. Such balls (tablets) are prescribed to the persons suffering from impotency. It has been claimed that such persons soon regain their vigour and strength.

(4) Live fishes such as Clarias batrachus, Heteropneustes fossilis and Channa sp. are valued for their high nutritive and medicinal properties.

(5) Sillago sihama is considered good and nourishing for nursing mothers.